IT IS 11pm on a wild windy night in the Cotswolds, but instead of being tucked up in bed, I am standing on a bridge carrying a muddy lane over a railway line.

Spotlights on a diesel locomotive and an excavator glow below me as engineers prepare for another night’s work reinstating double track on the Cotswold Line, as part of a £67m improvement scheme.

The work is taking place overnight to minimise disruption for passengers.

Stretching away into the dark behind the locomotive are wagons laden with 1,344 concrete sleepers. They will be unloaded and placed, seven at a time, on half-a-mile of the stone-covered trackbed within three hours.

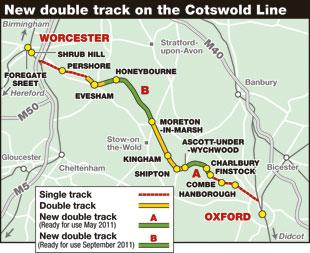

This is Dorn cutting, near Moreton-in-Marsh, in Gloucestershire, a little over half way between Oxford and Worcester.

A mile north, stone chippings are being unloaded and spread to form a base for the track, while at Moreton-in-Marsh another team is inspecting track that was fixed together by a machine the previous night, tightening the clips holding the rails to the sleepers if necessary.

We descend into the cutting to watch the sleepers being lifted from the train and positioned, using a hydraulic attachment on the excavator’s arm, which spreads out to drop the sleepers at the correct spacing, ready for a team moving up behind to fit the rails.

Lee Moyle, the site manager for tracklaying contractor AmeyColas, is proud of the progress being made, with a competitive spirit among the gangs carrying out different tasks, all aiming to complete half-a-mile of work per night.

He said: “We have a dedicated team on this project who know exactly what to do, day by day.

“We leave the machines parked along the line, so they’re in the right place ready for work every night and a setting-out gang works through the day to place markers for the night team.”

David Northey, the Network Rail project manager, said: “The process is like a conveyor belt, a series of different tasks taking place step by step.

“We’re using quite simple methods, without much mechanisation.”

However, this approach has not hindered progress, with work running ahead of schedule and on budget.

Mr Northey added: “They’re doing exceptionally well, especially as there’s a very tight window every night, with perhaps five hours’ actual work in an eight-hour possession, due to preparation, bringing in the supply trains and clearing up to make the line ready for the morning trains.”

Installation of four miles of track in west Oxfordshire is currently suspended, due to December’s snow disrupting the schedule.

AmeyColas has already laid a mile of track, including a section through Charlbury station, but the engineers will return in April to complete the section to Ascott-under-Wychwood before they install a new point east of Charlbury, from where single track will remain to the edge of Oxford.

The new track in Oxfordshire, along with extra platforms at Charlbury and Ascott-under-Wychwood stations, will come into use at the start of June.

The remaining 16 miles of new track, between Moreton-in-Marsh and Evesham, in Worcestershire, will open to trains in August.

Supply trains for the project mostly run from Oxford’s Hinksey Sidings, while old stone cleared from the trackbed is taken by rail to Appleford sidings, near Didcot, where it is recycled.

The aim of the redoubling project is to improve punctuality and reliability on the route, which now has many more services than in 1971, when it was decided to remove much of the double track to save money.

- Cotswold Line redoubling facts:

- 40 miles of steel rails are being delivered in sections up to 220m (720ft) long, which are welded together on site, to make up the 20 miles of new track

- 35,000 concrete sleepers will be laid

- 1,500 tonnes of stone chippings are delivered each night

- 5,000 Roman snails, which are a protected species, have been moved from the area around Charlbury station to make way for the new track, westbound platform and footbridge.

- For more details of the project, see the Network Rail website.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here